Reduce Ouflow of Carbon by Renovation of Industrial Machinery-ROCRIM

Reaching People In Need (RPN)

Reaching People In Need (RPN)

Bangladesh’s industrial sector facing significant challenges, impacting both biodiversity and the livelihoods. The environmental pollution in Bangladesh is being magnified and complicated due to rapid industrialization without due attention to the environment. We believe, industrial pollution, which is often perceived as an undesirable result of climate change, is a topic that will continue to be at the top of international cooperation’s agenda over the next decade. So, now is the best time to take initiatives of RPN’ for reducing pollution and increasing productivity of industries through longstanding industrial resources management and upgradation and re-engineering of industrial machinery that will contribute to climate change actions and fostering circular economy.

The “Reduce Carbon Emission through Modification & Re-Engineering of Industrial Machinery” project proposes a holistic approach to address the climate challenges and increase green efficient productivity of industries. Through this intervention we will introduce the new innovation system developed by ADT Green Technologies to reduce water consumption ratio during yarn or fabric dyeing and convert the produced heat into alternative energy. The new innovation is that reduce water consumption ratio during dyeing and another innovation is that introduce provision for re-use of water once used. At present water consumption ratio is 1:6 or 1:8 for yarn or fabric processing in textile industries that is generally extremely high. Making a single cotton shirt requires 2700 liters of fresh water. This amount equals a person’s drinking needs for 2.5 years. So, it is very important to reduce water consumption ratio 1:4 instead of 1:6 or 1:8. The simple equation is that more water use means create over pollution. If the use of fresh water in yarn processing can be reduced, then the use of water, energy, and chemicals will be automatically reduced which creating positive impact on environmental conservation & human health as well as increase green productivity which practice circular economy. Another innovation is protected ozone layer by minimizing heat emissions from generator exhaust and other heat generating machine.

Joint collaborations with ADT Green Technology, Bangladesh, Aggertech, Turkieya, Trakya, Turkieya and Tesmak, Turkieya is been implementing these activities. Through the project, on one hand, we will protect environment from climate change and on the other hand, making capable for higher green efficiency and productivity in the textile, dyeing, garment and washing plants which encapsulates 100% effluent water treatment and recycling, resulting water, chemical and gas will save.

As a part of the project, to finding innovative new ways to protect environmental pollutants and combat the climate crisis, we’ll describe below about the vital work we’re doing;

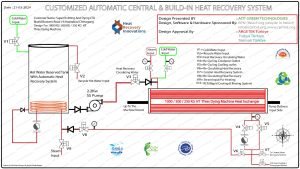

Introduce Water Recycling and Heat Recovery System in Industrial Sector:

Design of Heat Recovery System in Super Knitting & Dyeing Mills Ltd. Bangladesh.

Work Going on Heat Recovery System at Super Knitting & Dyeing Mills Ltd.

Work Going on Heat Recovery System at Super Knitting & Dyeing Mills Ltd.